Enabling the Open Chiplet Economy

Reduce Schedules, Eliminate the Interposer, Dramatically Improve D2D Interface

Chiplets are becoming ubiquitous in the Accelerated and Embedded Computing SoC markets. Unfortunately, several pain points are slowing the growth of the open Chiplet economy. The requirement and availability of expensive interposers, Die to Die Interfaces that consume excessive die area and add latency, and captive chiplet integration processes stand out as primary roadblocks for many customers.

CrossFire’s mission is to make the Chiplet ecosystem available to all. Foundry and flow agnostic, CrossFire offers a holistic and non-captive approach to Chiplet development and integration with a suite of products to shorten time to market and reduce costs.

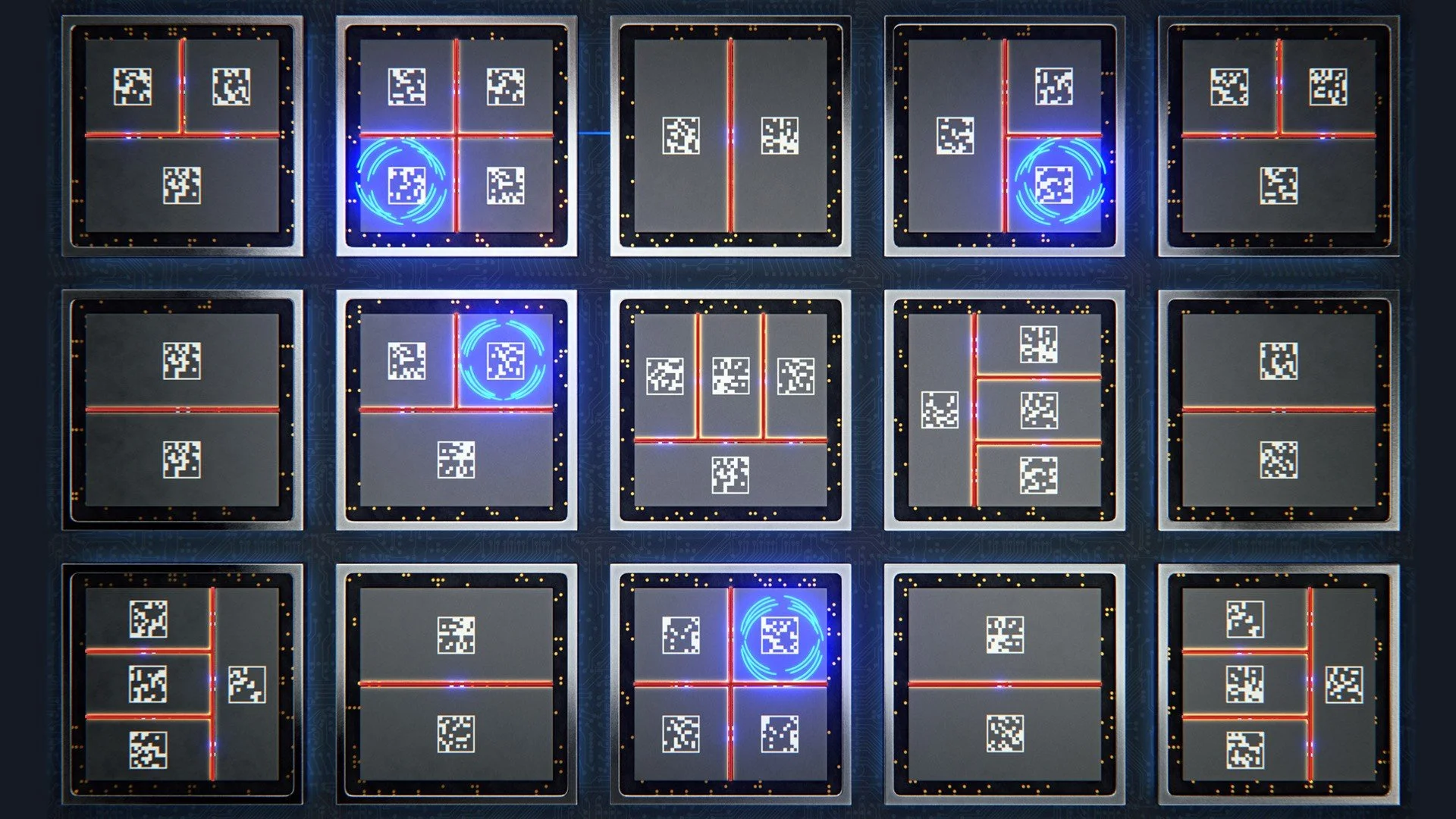

The product suite includes, CrossFire’s Bridgelet™ which can shave up to a year off of development schedules as well as reduce valuable interface die area by 50x and lower power use by 10x with the included Direct Chiplet Interface™(DCI). CrossFire also offers OmniDie™, a unique approach to chiplet integration that does not require interposers or an expensive package laminate, which can shorten development schedules and reduce costs.